The True Cost of Precision: What Every Australian Business Needs to Know About Cleanroom Construction

Beyond the Square Metre

When executives first consider building a cleanroom, they ask: "What will this cost per square metre?" It's reasonable as a decision maker, but not the right approach.

Cleanrooms are among the most technically complex environments in modern construction. Precision-engineered spaces where the air itself is a critically controlled parameter, where every surface must smooth and cleanable, and where a single oversight can mean the difference between regulatory approval and expensive retrofits months later.

At Connected, we've spent years navigating this complexity across radiopharmaceutical facilities, sterile manufacturing suites and pathology labs. The real cost isn't just monetary. It's in the decisions made long before construction begins.

What Actually Drives Cost

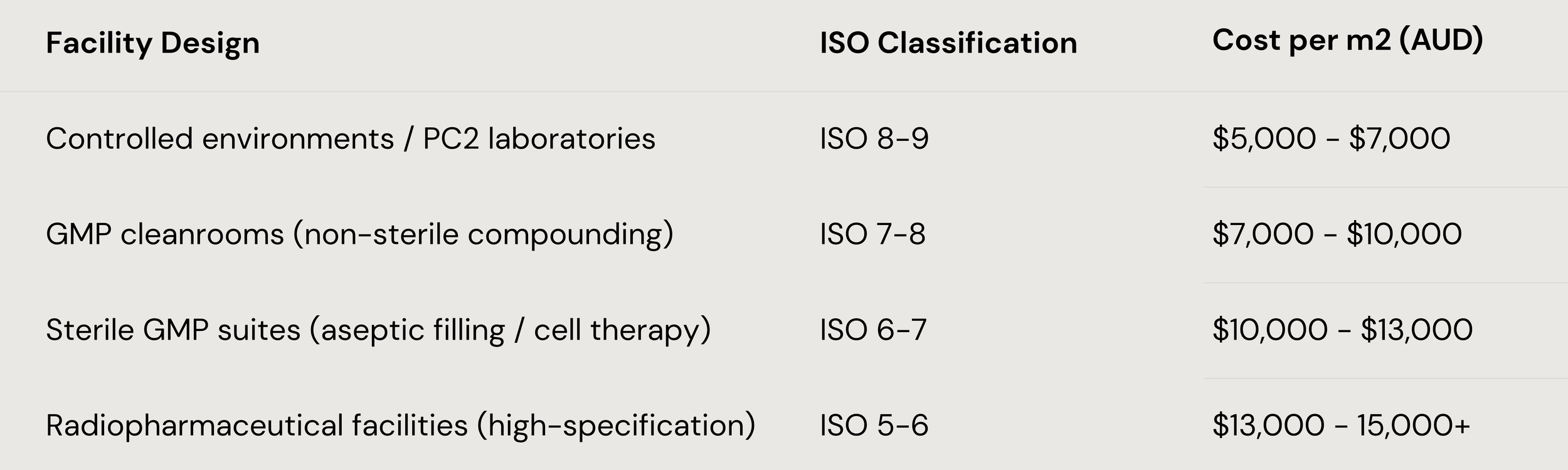

The difference between ISO classifications isn't academic. Moving from an ISO 8 environment to an ISO 5 space doesn't just represent a cleaner room. It represents an entirely different engineering challenge. Each classification increase can add 15 to 25 per cent to construction budgets through tighter HVAC control, sophisticated monitoring systems and materials that withstand validated cleaning protocols.

Consider what happens inside an ISO 5 cleanroom. Air changes completely dozens of times per hour through HEPA filters capturing particles smaller than a human hair. Pressure cascades ensure air flows from cleaner to less clean areas, never the reverse. Environmental monitoring tracks temperature, humidity and particle counts in real time. This isn't excessive. It's what's required when manufacturing therapies injected directly into patients.

Here's what catches organisations off guard: the building you choose matters almost as much as the cleanroom you build inside it. Poor property selection can inflate costs by 30 to 40 per cent through retrofit inefficiencies. Low ceilings force compromises in air handling design. Inadequate floor loading triggers structural upgrades. Insufficient electrical capacity means expensive service upgrades before cleanroom construction even begins.

Building services typically consume 60 to 70 per cent of total fitout cost. The HVAC system alone represents the largest single cost driver. Brands like Trox, Camfil, Munters and Stulz dominate because their systems reliably maintain tight parameters year after year. These aren't commodity units. They're precision instruments that must perform flawlessly because regulatory approval depends on it.

What to Expect in 2026

Australian market costs reflect both technical complexity and broader economic pressures. These aren't inflated numbers, they reflect the extraordinary levels of control these environments require.

Note: For aseptic filling operations, Grade A environments are required, though isolator background environments can be Grade C (ISO 7).

How Connected Delivers Differently

Our work with a radio pharmaceutical company demonstrated what's possible. We transformed a three-level residential building in Melbourne into a 540 square metre state-of-the-art radiopharmacy facility. The basement houses ISO 7 cleanrooms (hotlabs). The ground floor incorporates patient diagnostic areas with extensive radioactive shielding. The top level has administrative offices and a PC2 laboratory.

Success didn't come from bigger budgets or longer timelines. It came from integrated planning that anticipated challenges before they became problems, technical expertise that knew what radiopharmacy facilities actually need, and a delivery model aligning everyone around shared objectives.

Our LECI model (Lump Sum Early Contractor Involvement) exists because traditional procurement is fundamentally broken for complex projects. When design and construction are separated, misunderstandings multiply, variations proliferate and finger-pointing becomes default. No one owns the whole because no one is responsible for the whole.

We've replaced fragmentation with integration. Strategy, design and construction teams work as one unit from early engagement through final handover. Real-time subcontractor review means buildability and cost insights inform design development. Progressive optimisation finds efficiencies without compromising outcomes. Single-point accountability means one team providing answers and solutions.

Results speak: BVAQ Laboratory consolidated three facilities into a 9,500 square metre campus, now Australia's largest food testing laboratory. ALS Laboratory's transformation eliminated services issues plaguing original documentation. These weren't just construction projects. They were business transformations enabled by facilities that actually work.

Behind every project sits our commitment to safety, quality and environmental responsibility. Three years of zero lost-time injuries through structured safety leadership. ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 accreditation demonstrating systematic approaches tested daily.

The Real Question

Organisations that get cleanroom projects right don't hire contractors. They engage partners who understand what they're trying to achieve and have technical depth, integrated delivery capability and proven track record to deliver with certainty. They recognise the lowest initial bid often comes with hidden costs materialising as variations, delays and compromises.

Early engagement isn't an expense. It's the smartest investment you can make. When expertise converges from day one, when challenges are identified and resolved before becoming problems, when everyone aligns around clear objectives, projects don't just succeed. They create lasting value extending well beyond handover.

The question isn't whether cleanroom construction is expensive. The question is whether you're investing in a facility serving your organisation's needs reliably for years, or just buying square metres at the lowest price and hoping for the best.

One approach builds capability. The other builds risk.

Ready to discuss your cleanroom project?

Connect with our team to explore how our expertise in pharmaceutical, radiopharmaceutical, pathology and testing facilities can deliver certainty for your next build.

Connected. The better way to build.